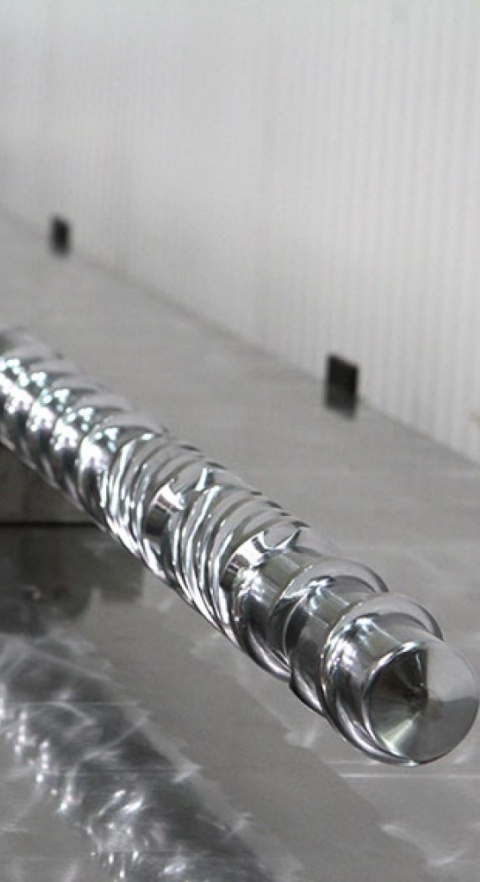

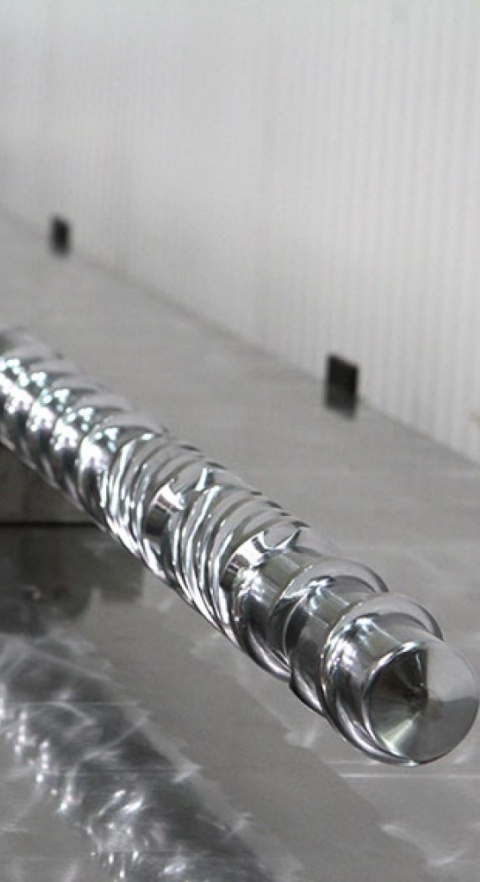

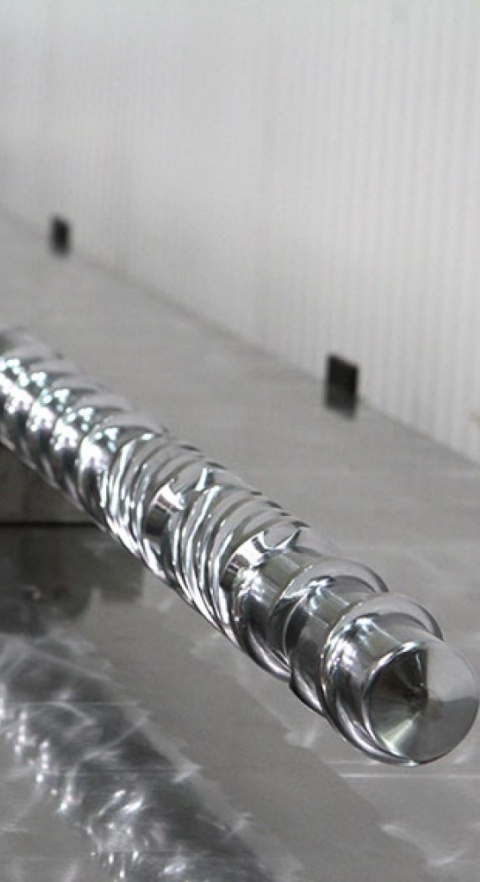

Chuangri’s recycling and pelletizing screws provide green solutions for customers. High-quality nickel-based alloy and tungsten carbide alloy layers make the screws and barrels more reliable, wear-resistant, and corrosion-resistant, significantly extending their service life. This ensures the production of pure and uniform products. Our aim is to enable an efficient recycling process, helping you transform waste into reusable raw materials.

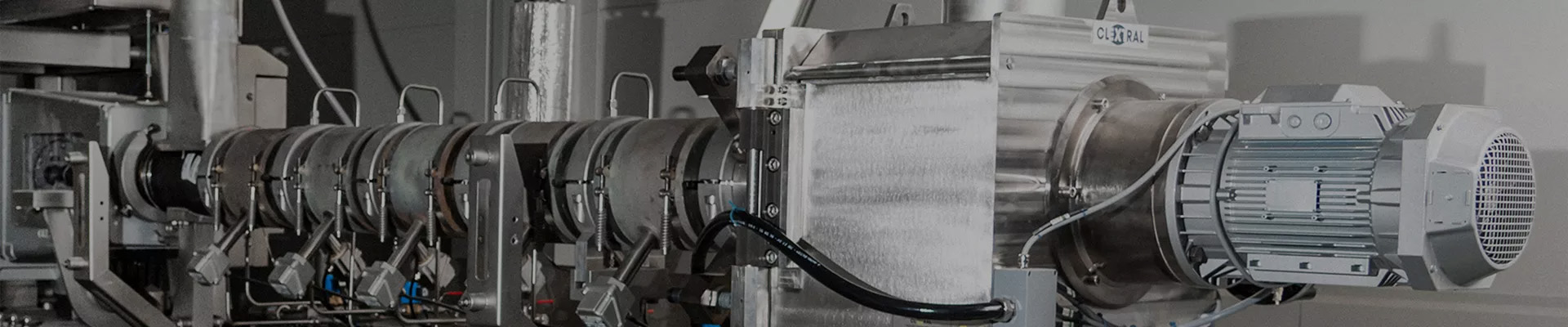

The barrel can be produced up to 12 meters in length without welding, ensuring a seamless structure that better captures the polymer.

HVOF tungsten carbide coating is well suited for processing highly filled or corrosive resins.

It improves color uniformity and speeds up material/color changeover, thanks to its self-cleaning action.

Recycling Pellet

How to customize

-

Submit your machine information and connection dimensions, along with a brief description of your needs.

Prepare a set of calipers and a tape measure, and simply provide us with your extruder/injection molding machine nameplate and connection dimension table.

Our team will communicate with you to understand your screw and barrel size information, the products being produced, the materials used, and your specific requirements (e.g., higher output or longer lifespan).01/04 -

Receive a quotation and feedback

After receiving your request, we will review it within 3 hours and provide feedback. Our team will consult you on materials, technical processes, and modifications that can make your concept manufacturable, along with a quote.02/04 -

Create drawings and revision checks

Our engineering team will provide assembly drawings of the screw and barrel within 2 days. We will double-check these against your machine to ensure all dimensions match, avoiding installation issues.03/04 -

Pay the deposit and commence production

Upon receiving your deposit as agreed in the contract, we will begin production within 1-2 days. The efficiency is based on our advanced equipment and annual production capacity. We can deliver your custom screws and barrels in optimal condition within 30 to 40 days.04/04