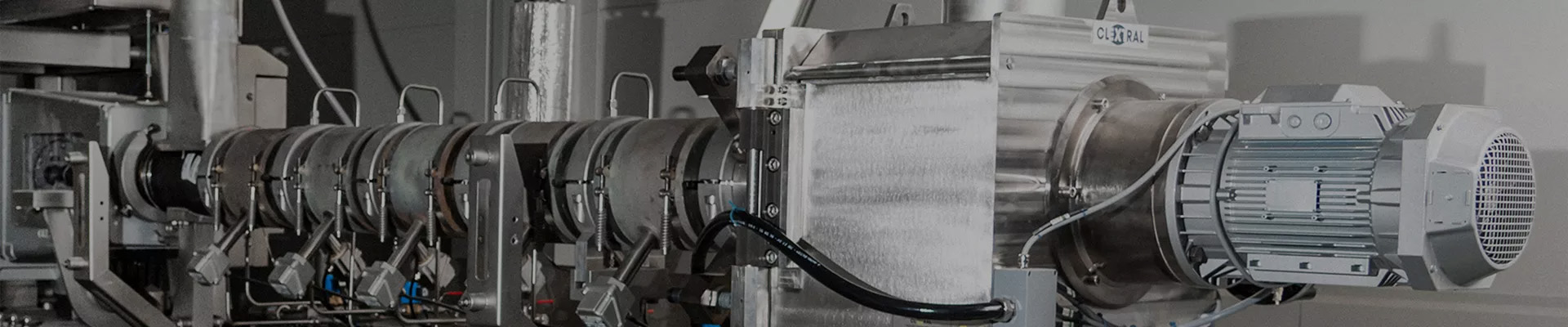

Injection molding

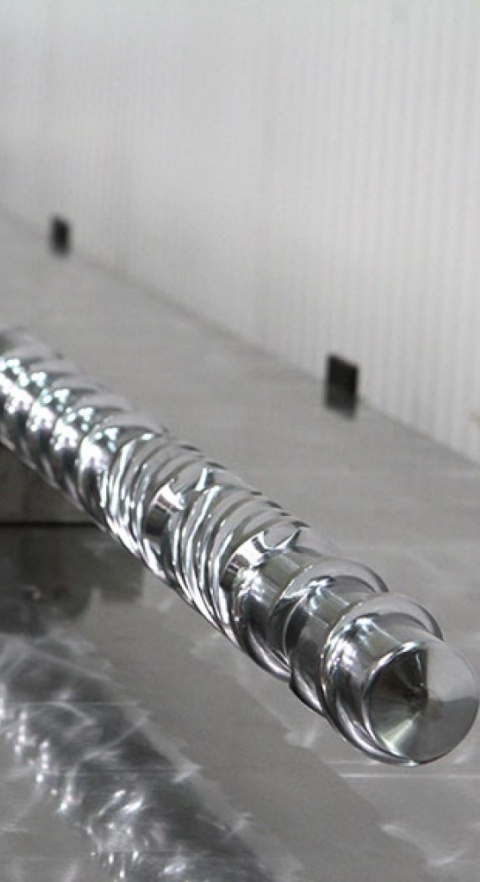

ChuangRi is constantly innovating to improve our injection molding solutions for a wide range of end product applications, like auto parts, components of electronic products, packaging and toys. Our injection screws are superior to industry standards.The design can be adjusted according to process requirements to optimize output,shear and mixing performance.

The robust design can handle a wide variety of resin materials

Effectively controls shear stress

Optimizes plasticizing performance and achieves uniform melt quality at high processing speeds