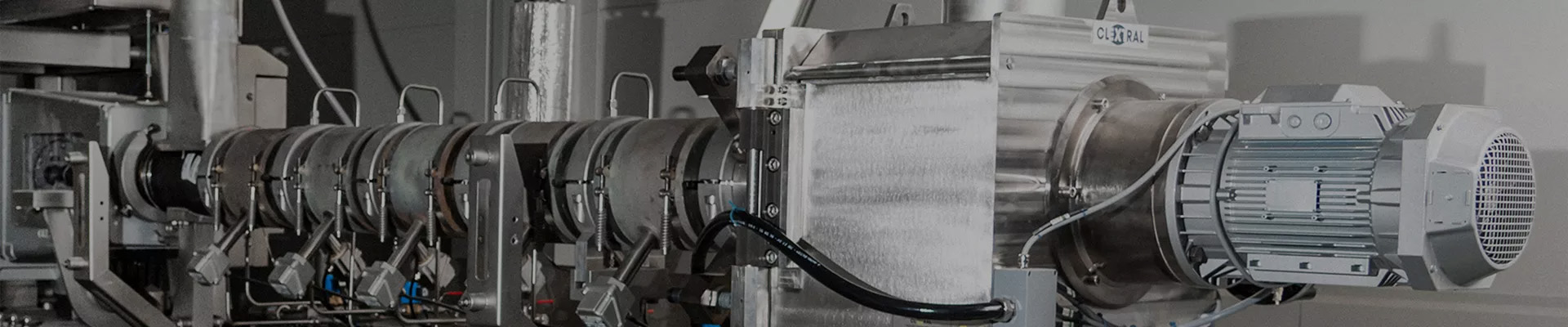

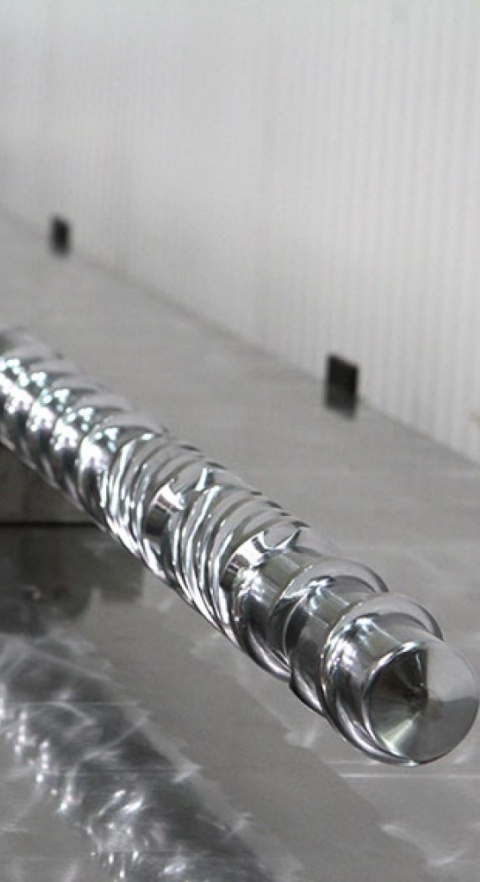

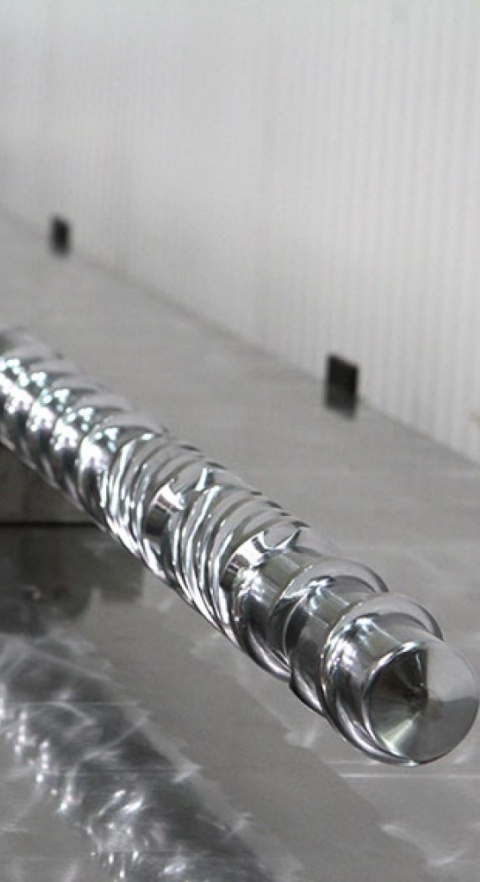

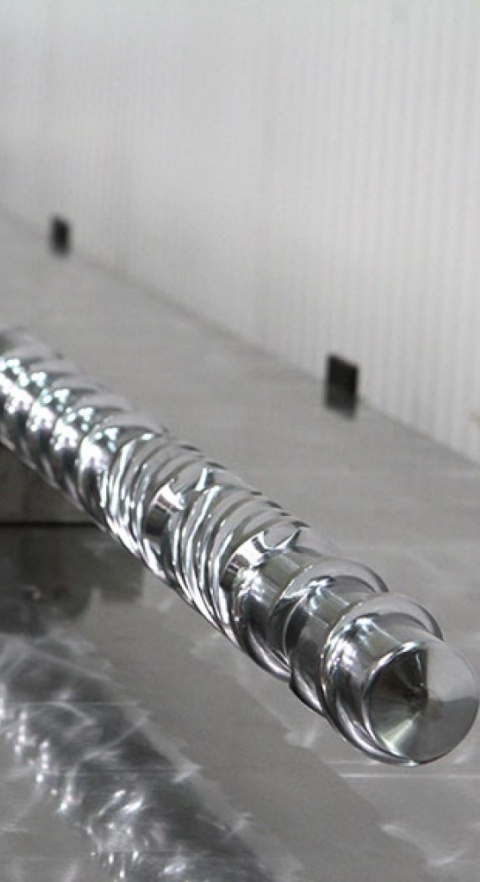

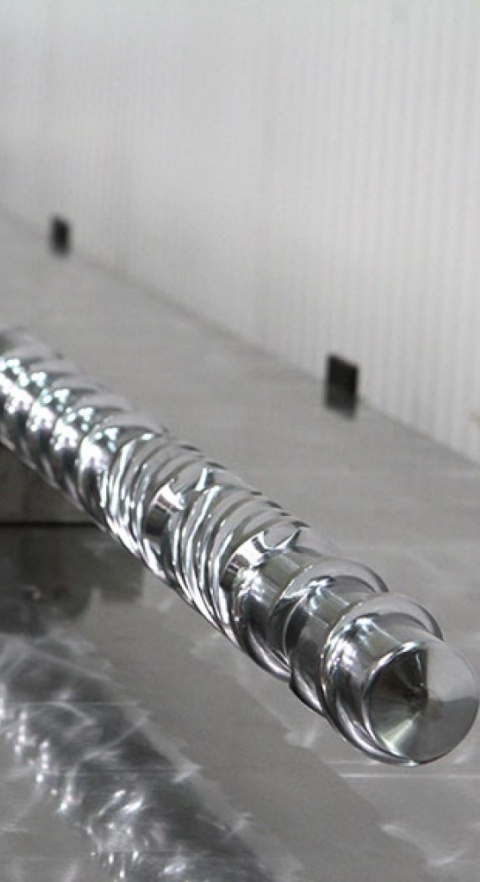

The conical twin-screw barrel is specially designed for the production of WPC boards, doors, foam boards, SPC flooring, and all PVC products. The advanced bimetallic and SKD inner lining technology can handle both virgin and recycled materials, with the raw material capable of incorporating 5%–300% calcium carbonate. In environments with any calcium carbonate ratio, we have extended the screw lifespan by over 30%.

SKD inner lining technology: Installed in different areas as needed to reduce internal wear of the barrel.

Tungsten carbide alloy combined with ceramic dual-layer alloy coating technology in the discharge and mixing zones, focusing on protecting the high-wear areas of the screw, extending its service life.

Various structural designs for high calcium, medium calcium, and low calcium: Due to the diversity of PVC raw materials, each company uses different calcium carbonate ratios, which vary greatly. We offer over 10 different screw structural designs to accommodate varying raw material ratios, improving output and plasticizing efficiency.

Board

How to customize

-

Submit your machine information and connection dimensions, along with a brief description of your needs.

Prepare a set of calipers and a tape measure, and simply provide us with your extruder/injection molding machine nameplate and connection dimension table.

Our team will communicate with you to understand your screw and barrel size information, the products being produced, the materials used, and your specific requirements (e.g., higher output or longer lifespan).01/04 -

Receive a quotation and feedback

After receiving your request, we will review it within 3 hours and provide feedback. Our team will consult you on materials, technical processes, and modifications that can make your concept manufacturable, along with a quote.02/04 -

Create drawings and revision checks

Our engineering team will provide assembly drawings of the screw and barrel within 2 days. We will double-check these against your machine to ensure all dimensions match, avoiding installation issues.03/04 -

Pay the deposit and commence production

Upon receiving your deposit as agreed in the contract, we will begin production within 1-2 days. The efficiency is based on our advanced equipment and annual production capacity. We can deliver your custom screws and barrels in optimal condition within 30 to 40 days.04/04