Blown film extrusion

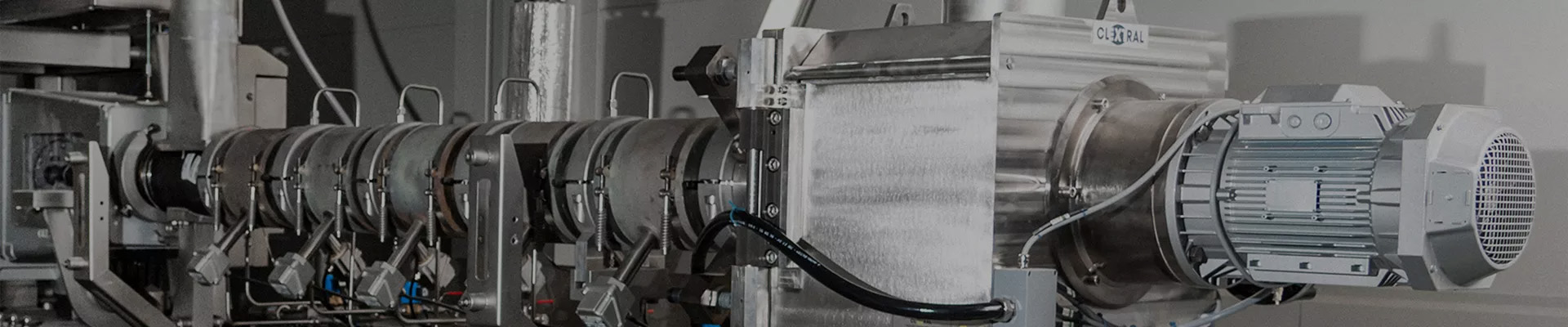

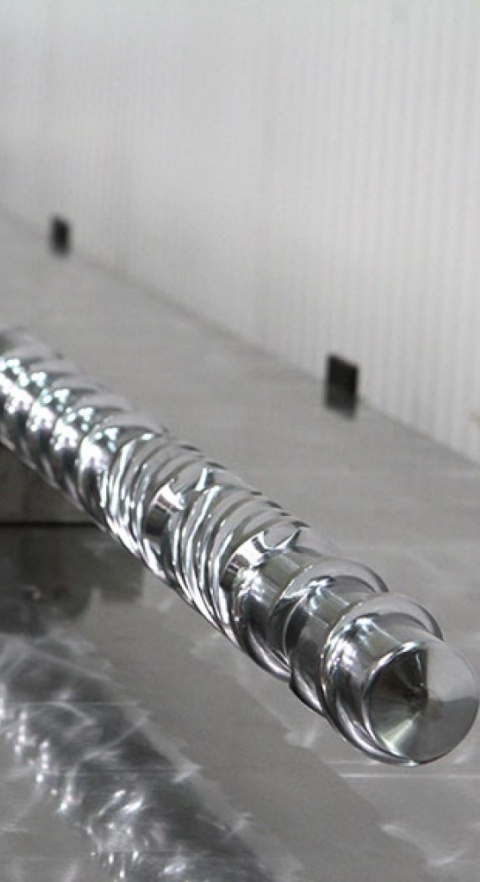

Over the years, Chuangri has continuously researched and improved the structural design of blown film screws. Currently, the most advanced and stable screw design is adopted, making it one of the most cost-effective screw options available. Compared to traditional screw designs, our screws deliver up to 20% higher output while offering superior melt temperature control and film uniformity, earning widespread customer satisfaction.

The overall output is increased through the design of double threads and pitch.

The melt homogeneity is enhanced by the design of the screw barrier.

The melt temperature control is improved due to lower shear stresses after melting.