Our service

We focus on the plastic extrusion and injection molding industries, providing feeder screws and barrels for all brands, models, and sizes.

-

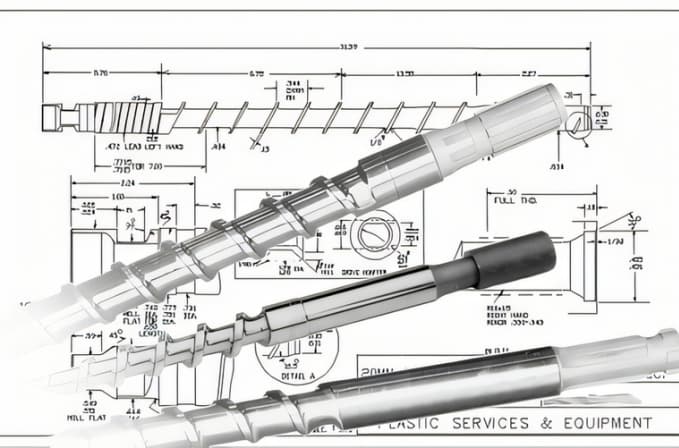

Screw DesignOur production success stems from our engineering expertise, working closely with you to design the most efficient screws tailored to your production line, ensuring optimal performance in extrusion or injection molding processes. Regardless of the type of plastic products you manufacture, we specialize in designing and manufacturing custom screws that enhance productivity and maximize profitability for your operations.

Screw DesignOur production success stems from our engineering expertise, working closely with you to design the most efficient screws tailored to your production line, ensuring optimal performance in extrusion or injection molding processes. Regardless of the type of plastic products you manufacture, we specialize in designing and manufacturing custom screws that enhance productivity and maximize profitability for your operations. -

CAD Design & EngineeringLet us work together to design the optimal feeder screw for your production line. Chuangri screws are designed to optimize your extrusion or injection molding processes. With any diameter and length, and compatible with any brand or model, we can design and manufacture custom feeder screws to improve productivity for your team.

CAD Design & EngineeringLet us work together to design the optimal feeder screw for your production line. Chuangri screws are designed to optimize your extrusion or injection molding processes. With any diameter and length, and compatible with any brand or model, we can design and manufacture custom feeder screws to improve productivity for your team. -

Screw ManufacturingChuangri's injection molding and extrusion screws are built to deliver consistent final product quality, high performance, and wear resistance. Using lathe operations, steel rods are processed into precise bars. These bars are irregular and are machined to specific dimensions. After machining, they are sent to a milling machine, where a process called “grooving” is applied, cutting deep grooves along the outer diameter in a spiral pattern. Hardfaced (carbide) alloys are then applied to the channels, becoming the top of the threads on the screw. The screws need protection from the harsh environment of the extruder. To ensure precision, they are placed on an OD grinder. Afterward, they undergo a belt polishing process, starting with coarse sandpaper and switching to finer grains to remove imperfections. Without such fine polishing, plastic may adhere to rough surfaces, hindering the process. Some screws are chrome-plated and then polished and ground. Finally, the drive end is attached to the screw, enabling it to be installed into the machine.

Screw ManufacturingChuangri's injection molding and extrusion screws are built to deliver consistent final product quality, high performance, and wear resistance. Using lathe operations, steel rods are processed into precise bars. These bars are irregular and are machined to specific dimensions. After machining, they are sent to a milling machine, where a process called “grooving” is applied, cutting deep grooves along the outer diameter in a spiral pattern. Hardfaced (carbide) alloys are then applied to the channels, becoming the top of the threads on the screw. The screws need protection from the harsh environment of the extruder. To ensure precision, they are placed on an OD grinder. Afterward, they undergo a belt polishing process, starting with coarse sandpaper and switching to finer grains to remove imperfections. Without such fine polishing, plastic may adhere to rough surfaces, hindering the process. Some screws are chrome-plated and then polished and ground. Finally, the drive end is attached to the screw, enabling it to be installed into the machine. -

Barrel ManufacturingBarrels are key components in injection molding and extrusion processes. Whether you’re aiming to reduce cycle times, improve melt quality and consistency, achieve more uniform melts, or enhance material quality by reducing excessive shear or long residence times, Chuangri offers custom-designed barrels to address the most challenging issues.

Barrel ManufacturingBarrels are key components in injection molding and extrusion processes. Whether you’re aiming to reduce cycle times, improve melt quality and consistency, achieve more uniform melts, or enhance material quality by reducing excessive shear or long residence times, Chuangri offers custom-designed barrels to address the most challenging issues. -

Production Speed & Emergency SolutionsWhen your equipment faces malfunctions, power outages, or capacity overloads, Chuangri can help you avoid production losses. Our customers are our top priority, and we work around the clock to ensure timely product completion while maintaining our high-quality and precision standards. Chuangri's factory operates 7 days a week to meet urgent demands.

Production Speed & Emergency SolutionsWhen your equipment faces malfunctions, power outages, or capacity overloads, Chuangri can help you avoid production losses. Our customers are our top priority, and we work around the clock to ensure timely product completion while maintaining our high-quality and precision standards. Chuangri's factory operates 7 days a week to meet urgent demands. -

Packaging & LogisticsChuangri screws and barrels are packaged with internal oil coatings and film wraps to prevent rust and damage caused by long-term transportation. They are then packaged in uniform wooden crates to withstand extreme conditions, ensuring safe and secure delivery to your facility. Our factory is located in the beautiful coastal city of Zhoushan, very close to Ningbo and Shanghai ports, allowing us to ship products to the port on the same day. We also support air freight and rail transport.

Packaging & LogisticsChuangri screws and barrels are packaged with internal oil coatings and film wraps to prevent rust and damage caused by long-term transportation. They are then packaged in uniform wooden crates to withstand extreme conditions, ensuring safe and secure delivery to your facility. Our factory is located in the beautiful coastal city of Zhoushan, very close to Ningbo and Shanghai ports, allowing us to ship products to the port on the same day. We also support air freight and rail transport.