What Are the Key Features of Injection Moulding Barrels?

What Are the Key Features of Injection Moulding Barrels?

Why is the Injection Moulding Barrel Crucial for Quality Production?

The Role of the Injection Moulding Barrel in Manufacturing Efficiency

The barrel of injection molding makes the manufacturing process effective and efficient in that it heats and melts raw plastic material prior to injecting into molds for effective and efficient manufacture of finished products. Properly designed barrels promote equal distribution of heat and complete melting in addition to interruption-free flow of materials, thus impacting precision and consistency of molded products manufactured.

The barrel of injection molding makes the manufacturing process effective and efficient in that it heats and melts raw plastic material prior to injecting into molds for effective and efficient manufacture of finished products. Properly designed barrels promote equal distribution of heat and complete melting in addition to interruption-free flow of materials, thus impacting precision and consistency of molded products manufactured.

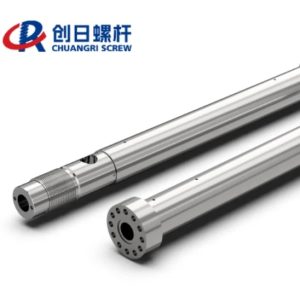

CHUANGRI SCREW’s barrels are made to meet specific manufacturing requirements while minimizing wear and maximizing production. Their injection molding barrels have a maximum length of 8000mm without splicing for higher straightness and strength. Additionally, the computer-controlled processing ensures maximum precision-fit between the barrel and screw, which maximizes output and product quality.

How CHUANGRI SCREW’s Barrels Enhance Precision and Consistency

The working material in plastic injection and extrusion operations has the potential to affect the screw wear of the machine significantly, with factors including abrasiveness, thermal properties, viscosity, and chemical reactions, among others. The Injection Molding Barrel is made up of superior quality metals like 38CrMoAlA, for example, that can produce durability along with supreme performance through nitriding operations as well as bimetallic coating or solid carbide treatment to provide improved strength and reliability in hostile environments.

The working material in plastic injection and extrusion operations has the potential to affect the screw wear of the machine significantly, with factors including abrasiveness, thermal properties, viscosity, and chemical reactions, among others. The Injection Molding Barrel is made up of superior quality metals like 38CrMoAlA, for example, that can produce durability along with supreme performance through nitriding operations as well as bimetallic coating or solid carbide treatment to provide improved strength and reliability in hostile environments.

In addition, CHUANGRI SCREW provides solutions designed for various plastic materials variations available in the market. If you are dealing with plastic types or those containing a significant amount of glass fibers, their barrels guarantee consistent melting and accurate management of shear stress. This tailored approach enables companies to attain top-notch melt quality when operating at increased speeds.

How to Optimize Your Injection Moulding Machine Screw Barrel?

Maintenance Tips to Prolong Barrel Lifespan

Making your injection molding machine screw barrel last longer comes through regular maintenance tasks, which not only prevents costly downtimes but also maintains production quality at a standard level.

Cleaning Best Practices for Optimal Performance

To keep the machine running at its capacity, it is essential to thoroughly cleanse the barrel after every production roundtrip. Effluents can deteriorate over time leading to clogs or inconsistent heating. Make sure to employ cleaning solutions that do not erode or harm the surface of the barrel. Avoid using tools that could potentially mark or weaken the inner coating. CHUANGRI SCREW’s barrels feature inner surfaces using advanced techniques to reduce plastic residue buildup during use and make cleaning easier.

Monitoring Wear and Tear Effectively

It’s important to check for any wear and tear to avoid operational problems in the future especially by keeping an eye out for thinning walls or uneven surfaces in the barrel interior and replacing any worn out parts promptly to prevent bigger issues later on.

Adjustments for Better Process Control

Adjusting the settings of your injection molding machine can greatly improve its performance when using a top-notch screw barrel from CHUANGRI SCREW. Make sure to tune the temperature zones and screw speed while also considering the material characteristics for optimal results.

CHUANGRI SCREW offers tailor-made designs to suit production requirements, such as:

- Temperature Control:Their barrels offer excellent heat dissipation capabilities due to advanced alloy compositions.

- Shear Stress Management:The robust design effectively controls shear stress while maintaining uniform melt quality.

- Material Compatibility:From household items to automotive parts and medical devices, their barrels accommodate diverse applications by optimizing plasticizing performance.

What Are the Common Challenges in Using an Injection Moulding Barrel?

Troubleshooting Issues with Injection Moulding Screw and Barrel

Injection molding screw and barrel systems are relied on heavily by manufacturing operations, but they tend to experience problems that can hamper production efficiency quality control is necessary to preserve optimum performance and guarantee product consistency.

Addressing Uneven Melt Flow Problems

Inconsistent melting behavior is a problem that can result in imperfections in the end product. This issue occurs when the plastic material does not melt evenly inside the injection molding barrel. To effectively solve inconsistent melt flow issues in manufacturing processes, modulating temperature zones and screw speed relative to material properties is critical for results.

CHUANGRI SCREW utilizes CNC machining methods to craft barrels with exact measurements and polished inner surfaces to guarantee even heat distribution and steady material flow for reduced chances of inconsistent melting outcomes. Moreover, their barrels are engineered to accommodate materials ranging from standard plastics to those with elevated glass fiber compositions.

Solutions for Overheating and Material Degradation

Excessive heating in the injection molding barrel can result in material deterioration which can lead to lower quality products and more waste being produced. Causes of this problem usually include much shear stress or the material staying in the barrel for too long.

Excessive heating in the injection molding barrel can result in material deterioration which can lead to lower quality products and more waste being produced. Causes of this problem usually include much shear stress or the material staying in the barrel for too long.

CHUANGRI SCREW utilizes processing techniques like nitriding and metalizing coatings to enhance durability and prolong usage duration. Barrels treated with nitriding exhibit a hardness ranging from 65 to 70 HRC rendering them ideal for challenging scenarios that require temperature management.

What Makes CHUANGRI SCREW’s Injection Moulding Barrels Stand Out?

Key Features of CHUANGRI SCREW’s Injection Moulding Barrels

CHUANGRI SCREW’s injection molding barrels are carefully constructed from top-grade materials among others, which are known for toughness and strength in addition to thermal stability properties in high-demand production environments with more resilience, thanks to high-level treatments such as nitriding and bimetallic coatings. Additionally, the bimetallic layer is corrosion-resistant with a longer lifespan than standard barrels. These characteristics render CHUANGRI SCREW’s barrels suitable for the use in industries processing normal plastics or products containing high glass fiber.

CHUANGRI SCREW utilizes advanced CNC machining technology in the manufacturing of injection molding barrels whose inner surface smoothness and size are required to enhance the homogeneity of molten material and give high-quality molded products. CHUANGRI SCREW’s injection molding barrels can efficiently handle a wide range of plastics including polymers and blends of resin with high fill rates. The sturdy construction helps regulate shear stress and maintain consistent melt quality at fast processing rates. Whether creating car parts medical equipment or household products, these barrels deliver reliable performance across various uses.

With more than three decades of experience in producing screw barrels, CHUANGRI SCREW has built a strong reputation for providing dependable products.

What is DHgate?

DHgate is a top online wholesale platform that connects buyers with suppliers across the globe. Founded in 2004 and headquartered in Beijing, China, DHgate focuses on offering an enormous variety of products from electronics and fashion to home goods, cosmetics, and more. DHgate primarily works with small and medium-sized enterprises looking for bulk purchases at affordable prices.

One of the most striking aspects of DHgate is that it can connect Chinese suppliers and manufacturers with worldwide buyers so that it becomes easy for companies to acquire low-cost goods. It makes safe transactions by employing escrow services to secure the buyer and offer a safe shopping experience. DHgate also includes order tracking, customer feedback, and a dispute resolution system to offer a hassle-free buying experience.

With over a million products available and shipping across the globe, DHgate has become a leading platform for businesses and entrepreneurs looking to source products and engage in international trade effectively. Whether you’re a small retailer or a large enterprise, DHgate offers a broad selection of goods to meet your business needs.

Frequently Asked Questions about Injection Moulding Barrel

Q: What is a barrel in injection molding?

A: The barrel is the pressure-carrying vessel with heat transfer demands for assisting in the plasticization of the material being processed. We specialize in bimetallic barrels and tool-steel-lined barrels. While more straight forward in design than complex screw and tip geometries the function is equally important.

Q: How to clean a barrel of an injection molding machine?

A: Remove the resin sticking on to the surface of the heating barrel with brass brush. Wrap the end of wood bar or bamboo with waste cotton cloth to clean the inside surface of the barrel (the cloth should be replaced several times during the cleaning process).

Q: How can the barrel’s performance be optimized for large-scale production?

A: Regular maintenance and adjusting injection pressure/speed enhance efficiency. Using wear-resistant materials for the barrel aligns with the context’s focus on durability and cost-effectiveness for mass production. Automated temperature control systems further ensure consistency, supporting high-volume output without quality compromises.