The Science Behind Injection Moulding Screw Recovery Techniques

The Science Behind Injection Moulding Screw Recovery Techniques

The Role of Injection Moulding Screws in Manufacturing

Importance of Injection Moulding Screws

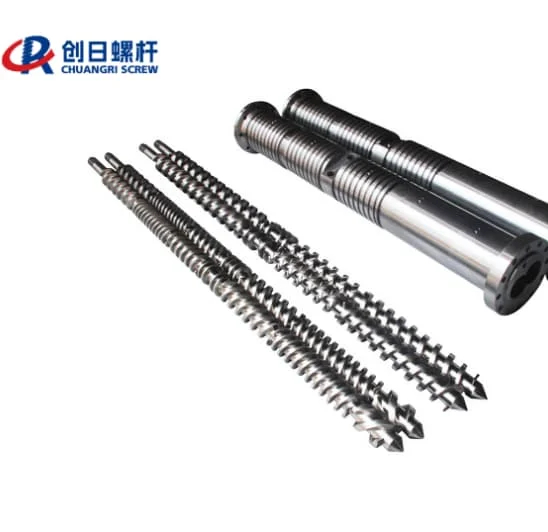

The screws used in injection molding are crucial in the manufacturing industry as they drive the plastic melting process in injection molding machines as a component of the system. They play a role, in moving materials and ensuring effective melting and controlled pumping to create high-quality plastic products. Screws perform three essential roles in plastic processing. First is the solid conveying. They could efficiently transport raw plastic pellets into the barrel. Then is the melting. They apply heat and shear force to homogenize the melt. Finally, it is metering. They deliver a consistent, pressurized flow of molten plastic into molds. The design and material composition of these screws greatly influence the efficiency and quality of injection molding processes.

CHUANGRI SCREW’s Contribution to Injection Moulding

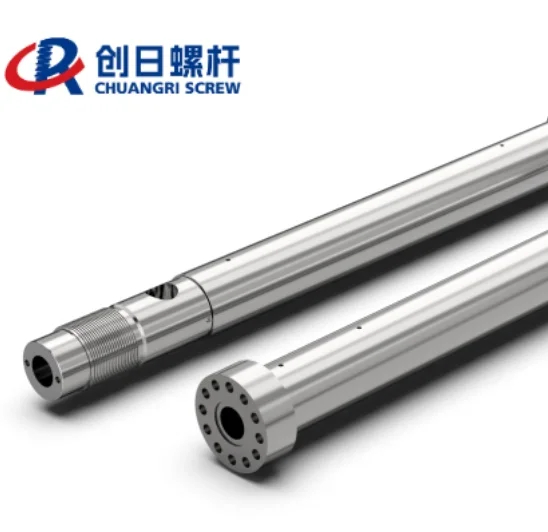

CHUANGRI SCREW has positioned itself as a figure worldwide in crafting and producing injection molding screws for over three decades now. It focuses primarily on tailoring screws that elevate efficiency and profitability in manufacturing processes. Its injection screw molding is optimized to deliver consistent product quality and durability with optimal performance. CHUANGRI SCREW is focused on excellence, which means that its products are tailored to meet various manufacturing processes.

Techniques for Enhancing Injection Machine Screw Efficiency

Optimizing Screw Design for Better Performance

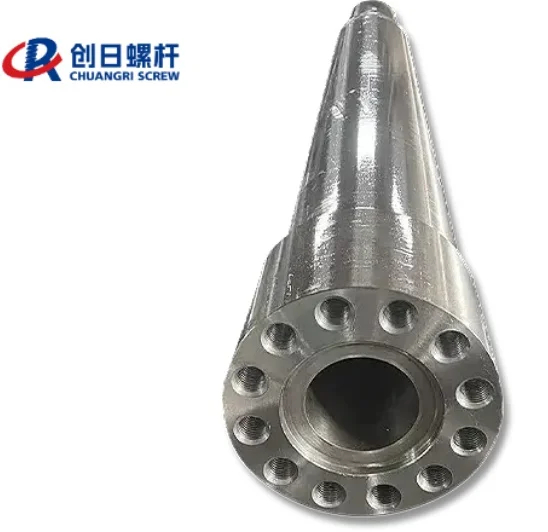

The screw design in an injection machine contributes to boosting its effectiveness. CHUANGRI SCREW employs CAD design and engineering techniques to create feeder screws that align with the unique needs of manufacturing lines. These patented designs are designed to maximize output by optimizing injection and extrusion molding processes. The Bimetallic Injection Molding Screw combines the simplicity and cost-effectiveness of traditional three-zone screws with the productivity and quality advantages of optimized material feeding, melting and metering zones. It is considered the best choice for injection molding applications.

Material Selection and Its Impact on Screw Recovery

The selection of materials to use in the manufacturing of screws on injection molding machines is responsible for how durable and functional they become over time. CHUANGRI SCREW proceeds and selects materials that conform to standards so the screws become long-lasting and are able to withstand wear and corrosion effectively. For example, the Nitrided Injection Molding Screw opts for high-quality materials such as 38CrMoAlA which enhances techniques used in the efficient extraction of screws.

Maintenance Strategies for Prolonged Screw Life

Regular Maintenance Practices

Keeping injection molding screws durable requires maintenance to preserve their longevity over time effectively. It’s crucial to perform inspections and upkeep routines to spot any wear and tear signs and prevent costly downtime. CHUANGRI SCREW emphasizes the importance of checks to maintain optimal performance and extend the life of their injection molding screws. Maintaining a regular schedule ensures that there is control of probable issues before they grow into serious issues leading to hassle-free operations and sustained efficiency.

Troubleshooting Common Issues with Injection Molding Machine Screws

Injection molding machine screws can face problems like aging over time through corrosion and low-performance efficiency issues brought about by these among others. Troubleshooting common screw issues including material degradation or burning, uneven melt homogeneity, premature wear and plastic adhesion. CHUANGRI SCREW stands out for its extensive knowledge of screw technology enabling them to offer effective solutions when troubleshooting is needed. Their team comprising of proficient engineers excels in identifying common issues and applying necessary measures to rectify them restoring the optimal functioning of the machinery.

Innovations in Screw Technology by CHUANGRI SCREW

Recent Advancements in Screw Technology

CHUANGRI SCREW continues to be an industry leader by introducing new screw technology through their tireless research and development that results in cutting-edge designs that boost levels of performance and efficiency to a significant degree. Their latest breakthroughs include using materials and coatings to enhance the durability and lifespan levels of their products. For Nitrided Screws, its surface-hardened for corrosion protection in PVC processing and extend lifespan by 30%. It also has breakthrough geometric designs. Take the blown film extrusion as an example, the double-thread screws with barrier zones increase output by 20%. This innovation enhances melt homogeneity and improves temperature control for uniform film thickness.

Frequently Asked Questions About Injection Moulding Screws

Q: What advantages do bimetallic injection molding screws offer for the processing of glass fiber-reinforced plastics?

A: Economical bimetallic injection molding screws enhance performance to process 15–50% glass fiber materials. They have hard alloy core materials (e.g., AISI 4340, SKD61) supported by wear-protective coating, optimizing the feeding, melting, and metering of material. This ensures high productivity with reduced abrasive wear from additives with uniform melt quality, and these are applicable to automotive parts, electronics and medical devices.

Q: How does CHUANGRI SCREW’s solid carbide screw handle ultra-abrasive materials and what industries are best served?

A: CHUANGRI SCREW’s solid carbide screws are engineered with advanced alloys like CPM 10V and Hastelloy C-276 that provide enhanced wear resistance for glass fiber-reinforced material up to 75%. Overall strength provides reduced degradation and longer life, even under harsh shear stress. The screws are a must in applications where accuracy and durability are a necessity, such as in the automotive (high-strength components), medical device (sterile, high-tolerance parts) and industrial machinery (abrasion-resistant applications) sectors.

Q: What is special about CHUANGRI SCREW’s injection molding screws as opposed to others available in the market?

A: CHUANGRI SCREW’s injection molding is carefully planned, prioritizing quality and efficiency, using CAD design and engineering techniques to create custom solutions that improve extrusion and injection molding processes effectively. They also use materials that are of international levels when it comes to strength and durability.