How Bimetallic Screw Barrel Improves Longevity and Performance

How Bimetallic Screw Barrel Improves Longevity and Performance

Enhancing Durability with CHUANGRI SCREW’s Bimetallic Solutions

The Role of Bimetallic Screw Barrels in Industrial Applications

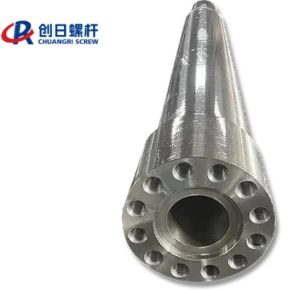

The use of bimetallic screw barrels is imperative in conditions such as plastic extrusion and injection molding processes where they must be able to resist severe heat and abrasive materials to efficiently and effectively process different plastics. CHUANGRI SCREW’s Bimetallic Barrel is specifically designed by distributing tungsten carbide particles within a corrosion-resistant nickel alloy matrix. This unique design guarantees that the barrels retain their strength and alignment after applying the wear-resistant alloy liner during the casting process.

CHUANGRI SCREW improves the strength and lifespan of its products through the use of technology in its barrels. The bimetallic barrel is known for its resistance to corrosion and wear in the industry making it a preferred option for operations dealing with harsh fillers. This innovative approach not only prolongs the equipment lifespan but also cuts down on maintenance expenses and operational disruptions a dependable solution for manufacturers seeking reliability.

Advantages of CHUANGRI SCREW’s Bimetallic Screw Barrels

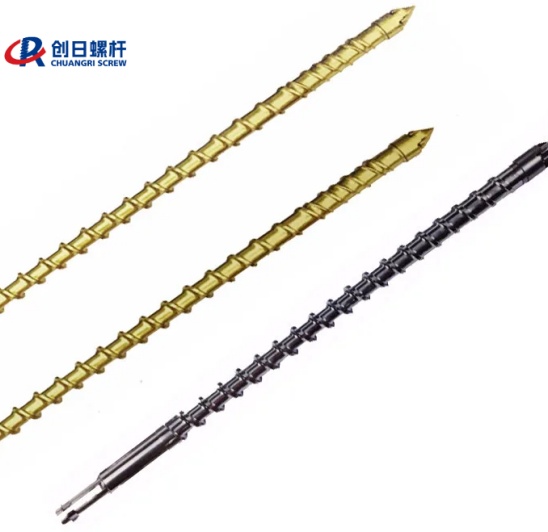

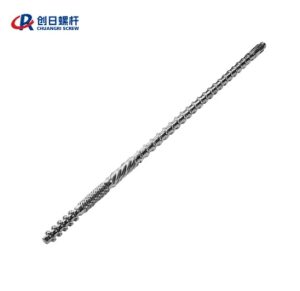

CHUANGRI SCREW’s bimetallic screw barrels have advantages compared to conventional designs with exceptional durability being one of the standout features. It enhances wear and corrosion resistance by applying a tungsten carbide alloy coating to the screw root diameter and outer diameter along with the screw threads surface. The cutting-edge coating method utilizes HVOF bonding technology to ensure 100% metallurgical bonding with the base material of the screw.

One more benefit is their capability to manage an amount of filler material without impacting efficiency negatively. The dual screw alloy coating made of bimetals is well suited for dealing with PVC materials containing a level of calcium powder. It can be utilized throughout the length of the screw. Selectively applied to areas that are more susceptible to wear and tear to guarantee top-notch performance in challenging scenarios.

Boosting Performance through Advanced Engineering

Performance Benefits of Using Bimetallic Barrels

The use of barrels during production provides valuable performance advantages because these parts are designed to possess higher heat stability at high-temperature conditions used in plastic molding or extrusion operations. Screws produced using these materials are resilient with a hardness level of up to 65-70 HRC and exhibit excellent resilience in harsh environments.

Apart from that, the use of barrels enhances product quality through the smooth flowing of molten material and prevention of material degradation. This leads to increased production rates. Improved final product features are both crucial for staying ahead in the competitive manufacturing industry of today.

Performance Benefits of Using Bimetallic Screws

CHUANGRI SCREW uses tungsten carbide alloy coating on the screw root diameter, screw outer diameter and the surface of the screw threads, significantly improving wear resistance and corrosion resistance. The HVOF metallurgical bonding technology is employed, achieving 100% metallurgical bonding with the screw base material. This solution addresses common issues of alloy detachment and peeling.

Another benefit of the Bimetallic Screw is the high-strength material compatibility. Constructed from premium alloys (e.g., AISI 4340, SKD61, 42CrMo), bimetallic screws maintain structural integrity under extreme mechanical stress and high-temperature conditions.

CHUANGRI SCREW’s Engineering Excellence

CHUANGRI SCREW demonstrates a dedication to top-notch engineering through its attention to detail in both product design and production processes. The company’s team of manufacturing engineers showcases extensive expertise and hands-on know-how that it uses to develop cutting-edge solutions customized to meet customer requirements. It supports both ODM and OEM services. The company provides full production services for screws and barrels from raw materials like metal alloys to finished goods.

Its commitment to excellence is also reflected in its quality checks and utilization of the most modern CNC machining tools. It guarantees optimum quality and performance by monitoring every phase of production at CHUANGRI SCREW according to global standards.

Cost Efficiency and Long-Term Benefits

Economic Advantages of Investing in Bimetallic Technology

Investment in two-metal technology is lucrative for manufacturers because it guarantees improved wear resistance and durability for screw barrels made of two metals. The life cycle of these barrels entails repeated replacement and reduced labor costs in the long term. This results in cost savings through reduced equipment downtime and improved production efficiency. Moreover, the two metal barrels’ resistance to filler content without affecting performance ensures consistent product quality that makes it cost-effective.

Bimetals investment may appear costly in the initial stages. It can save huge costs in the long term for businesses that are willing to cut costs and improve efficiency. Bimetals screws are an investment possibility that can save businesses maintenance costs and improve productivity levels in the long term.

CHUANGRI SCREW’s Cost-effective Solutions

CHUANGRI SCREW focuses on offering budget solutions tailored to suit the requirements of contemporary manufacturing settings. Their thorough production process involves the precise choice of raw materials and the application of the latest engineering techniques to guarantee that every part is up to standards of excellence in terms of quality and performance.

Conducting all the production operations in CHUANGRI SCREW’s facilities keeps costs under control and reduces clients’ supply chain costs, with competitive prices still achieved without compromising the quality standards of their products. Additionally, the company’s dedication to customer contentment shines through in its sales services that swiftly resolve any product concerns during the warranty period.

Frequently Asked Questions about Bimetallic Screw Barrels

CHUANGRI SCREW is dedicated to delivering customer service and support to ensure that customers receive top-notch products and assistance at every step of their journey with us. Our sales and after-sales teams know screws, barrels, and related items enabling them to promptly and effectively address all technical questions for clear communication. We go above and beyond in our commitment, to customer satisfaction; if any quality concerns emerge during the warranty period following order fulfillment we stand by our products until the matter is resolved satisfactorily. This method not fosters confidence but also guarantees that customers can count on CHUANGRI SCREW for continued assistance.

Q: What makes CHUANGRI SCREW’s bimetallic products superior?

A: CHUANGRI SCREW stands out for its barrels that feature top-notch materials like tungsten carbide and nickel alloys known for their outstanding durability against wear and corrosion challenges. The company’s cutting-edge engineering methods ensure a metallurgical bond with the screw’s base material to tackle common issues such as alloy detachment and peeling. CHUANGRI SCREW applies a tungsten carbide alloy coating to enhance wear resistance and corrosion protection at areas like the screw root diameter and outer diameter surfaces along with the threads.

Q: How does the lifespan of a bimetallic barrel compare to traditional options?

A: The longevity of a barrel surpasses that of conventional choices because of its improved toughness and resistance to wear and tear. The bimetallic barrel evenly spreads out tungsten carbide particles in a corrosion nickel alloy matrix to guarantee robustness and alignment even post-casting the wear-resistant alloy liner. This configuration leads to a prolonged lifespan that minimizes the need for replacements and related labor expenses resultantly aiding manufacturers in saving costs.

When businesses opt for CHUANGRI SCREW’s options, they can boost their ROI by cutting down on maintenance costs and improving productivity at the same time thanks to the top-notch product design and skilled craftsmanship. Providing solutions that bring quick wins and lasting financial advantages.