Exploring the Advantages of Bimetallic Barrels in Plastic Manufacturing

Exploring the Advantages of Bimetallic Barrels in Plastic Manufacturing

What Makes Bimetallic Barrels Essential in Plastic Manufacturing?

The Role of Bimetallic Barrels in Enhancing Production Efficiency

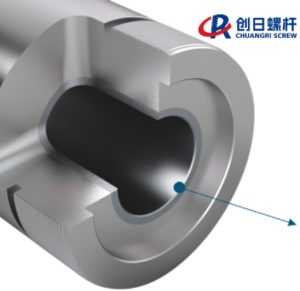

For injection or extrusion molding, the most critical components in the machine are the barrel and the screw. They must be machined with high-quality materials that are extremely tough and offer high temperature, wear and corrosion resistance. Bimetallic barrels improve production efficiency as they consist of two distinct metal layers (e.g., wear-resistant inner alloy + corrosion-resistant outer layer) to maximize performance.

CHUANGRI SCREW’s bimetallic metal barrels showcase alloy linings forged using a centrifugal casting technique that guarantees consistent thickness and durability across the board. This careful construction minimizes the wastage of materials. Enhances the uniformity of molten substances while optimizing temperature regulation in extrusion or injection molding operations.

How Do Bimetallic Screw Barrel Materials Contribute to Durability?

The strength of bimetallic screw barrel materials is a feature that sets them apart. CHUANGRI SCREW makes use of alloys such as tungsten carbide and nickel-based blends that are ideal for challenging conditions. The Bimetallic Barrel is very suitable for treating materials, such as engineering plastic or PVC corrosive. CHUANGRI SCREW makes use of the HVOF bonding technology for achieving complete substrate-alloy adhesion, and therefore achieving ideal performance and durability without worrying about spalling and shedding that results from traditional methods of bonding.

Why Choose a Bimetallic Barrel Over Conventional Options?

Bimetallic barrels may be a bit more costly at the front end; however, their extended life and better resistance to wear and corrosion mean you will save money in the long run. An investment in your machinery, ensuring the highest quality components and tools is essential for manufacturing the best quality products. Bimetallic barrels feature a unique engineering and design that allows them to better cool or heat, precisely controlling uniform area temperatures. They also increase barrel and screw life and are more resistant to wear, wear and corrosion.

How Do Bimetallic Barrels Improve Plastic Manufacturing Processes?

Reducing Maintenance Costs with Long-Lasting Materials

Use of barrels in the plastics sector has revolutionized the sector with their exceptional durability and ability to resist wear and corrosion extremely well. Through the use of corrosion-resistant construction, bimetallic barrels cut repair or replacement time, reducing maintenance. Their tough construction prevents constant failure through wear, enabling “Improved material utilization” and “No tooling expenses” through extended service life. This reduces operational interruptions and aligns with eco-friendly goals by lowering material waste, as referenced in “Eco-friendly Materials and Manufacturing Processes.”

By opting for CHUANGRI SCREW’s barrels, you can enjoy decreased periods of inactivity and decreased operational expenses. The longer lifespan of these parts prevents disruptions in manufacturing processes enabling companies to concentrate on increasing productivity without worrying about machine failures.

Enhancing Productivity Through Improved Heat Resistance and Strength

Resistance to temperature and durability of materials are essential factors in the manufacture of plastics. CHUANGRI SCREW’s bimetallic barrels shine in these aspects by delivering performance even under intense pressure situations. The technique of casting guarantees an even spread of the alloy layer across the barrel resulting in consistent hardness and density. This level of accuracy in engineering, enhances the regulation of temperature, during extrusion or injection molding processes resulting in uniform molten materials and a higher-quality end product.

For more than three decades, CHUANGRI SCREW has been specializing in crafting precision screws and barrels with utmost care and attention to detail. They have successfully executed over 4,600 projects across the globe establishing a reputation for their exceptional work in the field. From material choices to cutting-edge CNC machining methods. Guaranteeing that every item they produce meets the highest benchmarks for functionality and dependability.

Why Are CHUANGRI SCREW’s Bimetallic Barrels a Reliable Choice?

Advanced Manufacturing Techniques Used by CHUANGRI SCREW

CHUANGRI SCREW uses state-of-the-art manufacturing methods to make sure its bimetallic barrels perform exceptionally in production processes. CHUANGRI SCREW employs advanced manufacturing processes such as CNC machining and super alloy machining to ensure precision and scalability. Key techniques include:

- CNC Machining: Employed in precision manufacturing of complex screw geometries, with suitability for “Applicable Scenarios of CNC Machining” to companies that require tight tolerances.

- Machining of Super Alloy: Experience in machining difficult materials (e.g., stainless steel, titanium) for harsh-duty applications, offering corrosion resistance and long life.

- Custom Machining: Tailored solutions for individual client requirements, represented as “Custom Machining” in the scenario to addressing unique industrial needs.

CHUANGRI SCREW’s products are known for their commitment to environmental sustainability as well.The barrels of bimetallic material are designed with precision to ensure less wastage of material during processes promoting environmental practices. Additionally, the high thermal stability of barrels guarantees energy efficiency, enabling producers to save money and comply with environmental laws successfully.

CHUANGRI SCREW’s products are known for their commitment to environmental sustainability as well.The barrels of bimetallic material are designed with precision to ensure less wastage of material during processes promoting environmental practices. Additionally, the high thermal stability of barrels guarantees energy efficiency, enabling producers to save money and comply with environmental laws successfully.

When you opt for barrels from CHUANGRI SCREW, we will provide exceptional service to ensure a smooth experience for our customers worldwide.

Frequently Asked Questions about Bimetallic Barrels

Q: What is a bimetallic barrel?

A: Bimetallic screw barrels are made of two metals or two alloys of metals and are mostly coated with an extra layer of carbides and other commercial coating material. Bimetallic screw barrels are not a different type of screw barrel, like advanced designing. The same design screw can be made in a nitrided way and bimetallic way.

Q: What is the purpose of the vented barrel in the extrusion process?

A: Normally employed in extrusion, the vent ports are one or several openings in the barrel that will give devolatization of the polymer while processing. They remove impurities in the form of volatiles that will negatively impact the process and product.

Q: What are the advantages of using a bimetallic barrel in lifting or anchoring applications?

A: Bimetallic barrels have two metal layers (e.g., corrosion-resistant outer and high-strength inner alloys), which enhance durability in harsh environments like bridge construction. This aligns with the context focus on anchors (e.g., cast-in lifting anchors) requiring resistance to wear and dynamic loads for the long-term stability of structures.

Q: How does a bimetallic barrel improve performance in tilt-up or spherical head anchor systems?

A: The dual-material design mitigates thermal stress and corrosion, critical for tilt-up anchors exposed to moisture or temperature shifts. Its robust construction supports heavy loads, similar to spherical head rod/plate anchors while maintaining precision in alignment during lifting operations.