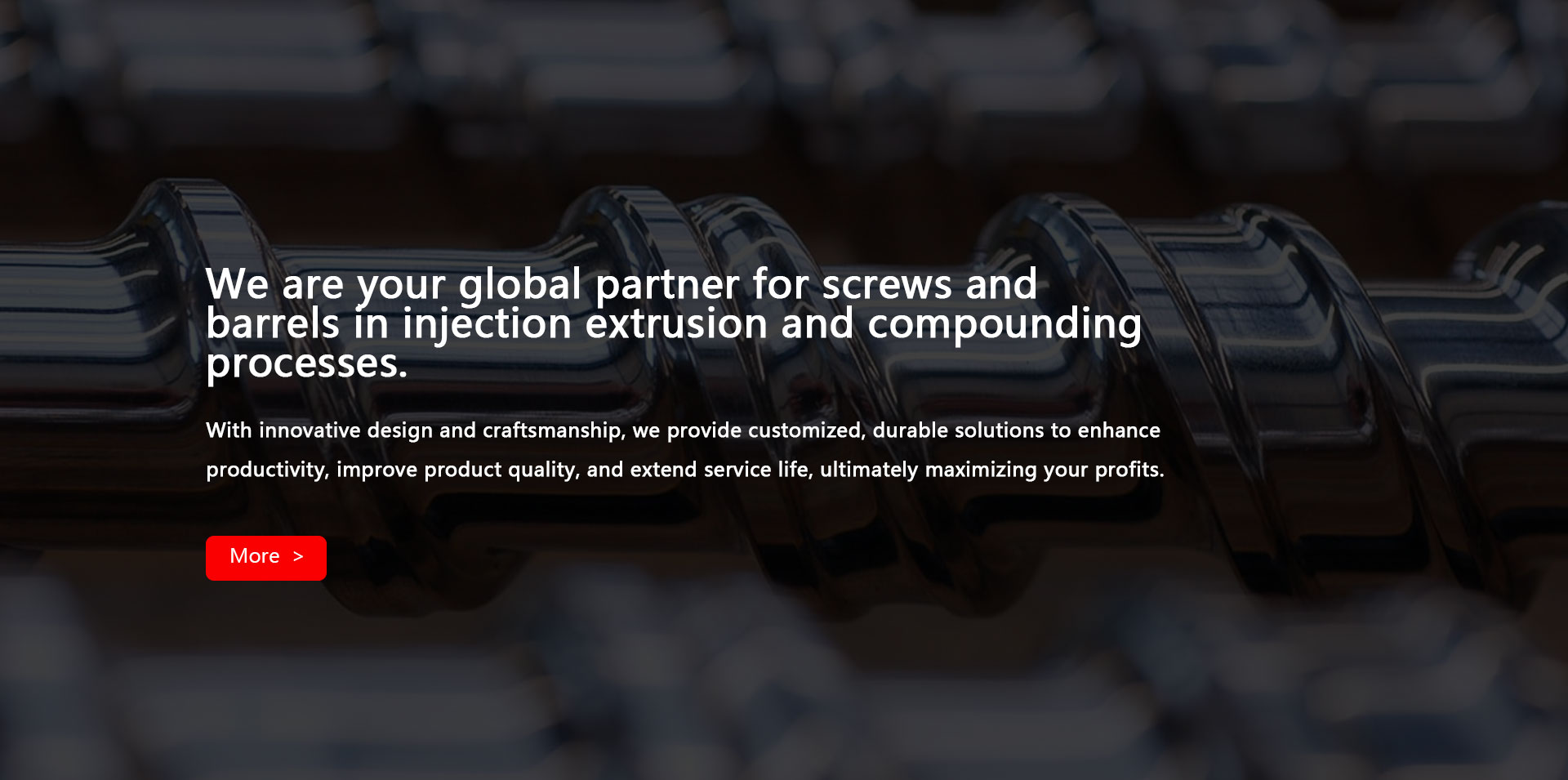

Your Screws Should Match Your Goals

Chuangri is a global leader in the design and manufacture of plasticizing equipment. As a family-owned business, we have continuously evolved since our founding in 1990. Chuangri's screws and barrels are designed to meet the specific requirements of your processes, minimizing wear, increasing output, and improving quality.

-

12500 ㎡ Factory Space

12500 ㎡ Factory Space -

60 + Employees

60 + Employees -

4600 + Projects

4600 + Projects -

30 + Export Countries

30 + Export Countries

-

R

R&DWe offer customized R&D based on customer and industry needs, modifying or re-engineering screw designs. -

E

ExpertiseOur sales and after-sales team are well-versed in screws, barrels, and related products, ensuring quick and efficient responses to all technical inquiries for effective communication. -

E

EfficiencyProduction can be scheduled on the same day once the drawings are confirmed, minimizing lead times. Standard stock models are shipped within 3 days. -

Q

QualityWe rigorously select raw materials, ensuring all steel data meets international standards. -

S

ServiceIf any quality issues arise within the warranty period after order completion, we take full responsibility until the issue is resolved. -

C

CostAll manufacturing processes are completed in-house, allowing us to control costs and reduce supply chain expenses for our customers.

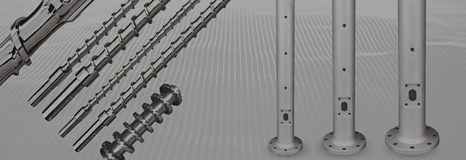

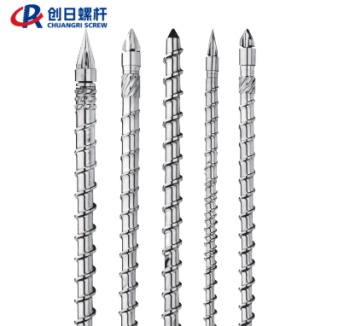

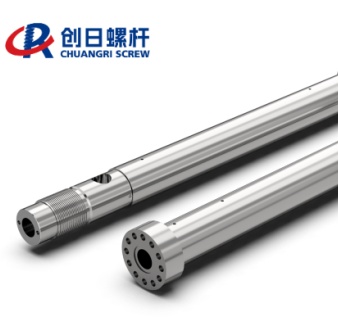

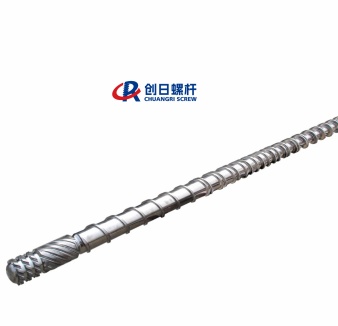

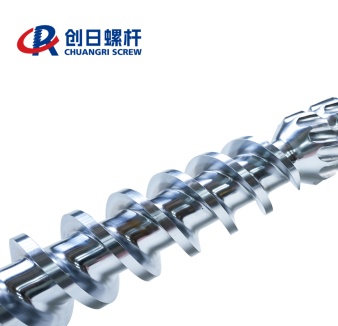

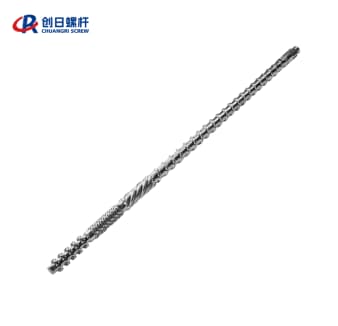

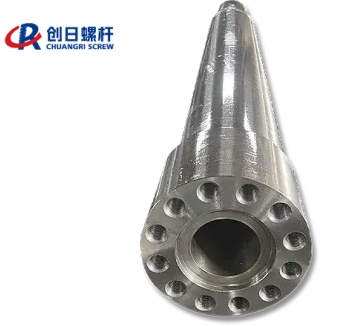

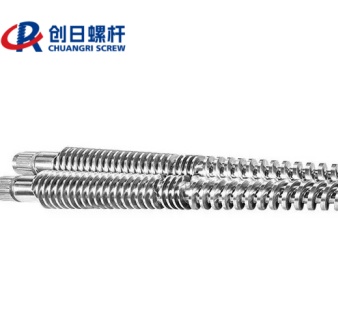

SCREW AND BARREL

SCREW AND BARREL SOLUTION

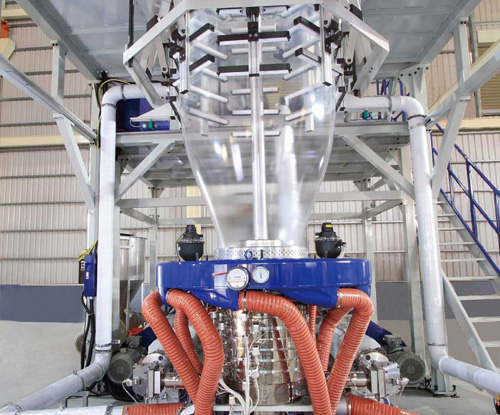

For many, "plastic" is often considered the same. However, different types of plastics can have very different processing characteristics. A screw performs three basic functions: solid conveying, melting, and metering or pumping. Let’s work together to design the optimal screw for your production line. CHUANGRI screws are designed to optimize your extrusion or injection molding process. With any diameter and length, and compatible with any brand or model, we can design and manufacture custom feed screws for your team, improving productivity.

CHUANGRI GLOBALIZATION

With over 20 years of experience in the production of screws and barrels, we serve more than 50 countries worldwide. We are dedicated to providing you with one-stop solutions for plastic machinery screws and barrels!